Industry Trends: Changes in the Wheel Market in the Coming Years

The automotive industry has long been one of the key drivers of economic growth and technological innovation. Among the various components of a vehicle, car wheels and rims play a crucial role in ensuring safety, performance, and efficiency. However, as the global automotive landscape evolves with new technologies and consumer preferences, the wheel market is also undergoing significant changes. This article addresses key questions regarding the future of the car wheel market, analyzing current trends, and exploring potential solutions.

1. What Are the Major Trends Shaping the Car Wheel Market?

Several key trends are expected to influence the car wheel market over the next few years:

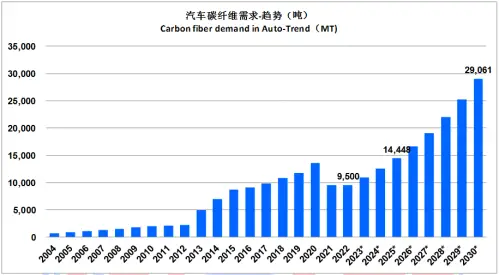

lGrowing Demand for Lightweight Materials: As car manufacturers strive to improve fuel efficiency and reduce carbon emissions, there has been a significant shift towards lightweight materials. According to the European Aluminium Association, lightweight materials like aluminum and magnesium are expected to account for 30% of the total vehicle weight by 2030. This trend is directly impacting the car wheel market, where manufacturers are increasingly using these materials to reduce weight while maintaining strength and durability.

lThe Shift Toward Electric Vehicles (EVs): The rise of electric vehicles (EVs) is also a pivotal trend shaping the car wheel market. With global EV sales expected to reach 40 million units by 2030, according to the International Energy Agency (IEA), the demand for wheel rim designed specifically for electric drive trains will grow. EV wheels need to accommodate higher torque and ensure smoother driving experiences, pushing manufacturers to innovate in terms of material selection and design.

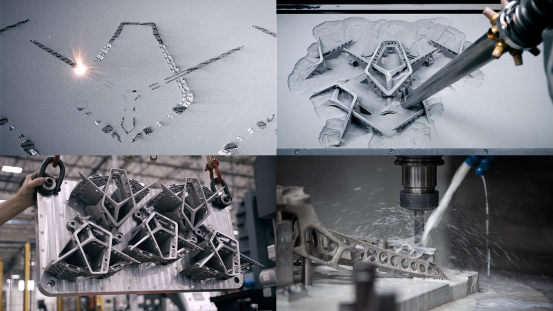

lAdvanced Manufacturing Technologies: The advent of additive manufacturing (3D printing) and other advanced manufacturing processes is revolutionizing the car wheel production process. These technologies offer significant cost-saving opportunities, greater design flexibility, and faster production timelines. By 2025, the global 3D printing market for automotive components is expected to grow to USD 3.6 billion, according to a report by MarketsandMarkets, further influencing wheel designs and production methods.

2. What Challenges Do Manufacturers Face in the Car Wheel Market?

While these trends present growth opportunities, they also bring several challenges for manufacturers:

lSupply Chain Disruptions: The automotive industry has faced numerous supply chain disruptions in recent years, particularly during the COVID-19 pandemic. Shortages in raw materials such as steel and aluminum have led to production delays and increased costs. These disruptions pose a challenge for car wheel manufacturers who need to maintain steady production schedules and meet the growing demand for high performance car rims.

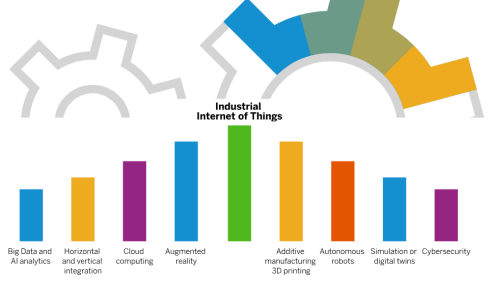

lTechnological Integration: With the shift towards EVs and advanced manufacturing processes, car wheel manufacturers need to invest in new technologies and production capabilities. The integration of advanced sensors and wireless technology into aluminum alloy rims for better performance monitoring presents both an opportunity and a challenge, as manufacturers must ensure that these innovations are viable in terms of cost-effectiveness and scalability.

3. How Can Car Wheel Manufacturers Adapt to the Changing Market?

To successfully navigate the evolving car wheel market, manufacturers must adopt strategies that embrace both innovation and sustainability. Here are several ways to adapt:

lInvest in R&D for New Materials: Wheel manufacturers should invest in research and development to explore new materials that offer both weight reduction and performance enhancements. This could include composites or new aluminum alloys that provide better strength-to-weight ratios. Collaboration with material science companies will be key to staying ahead of the curve.

lFocus on EV-Specific Wheel Designs: As the market for electric vehicles grows, manufacturers must develop car alloy wheels that meet the unique demands of EVs, such as higher torque tolerance and optimized designs for regenerative braking systems. Working closely with automakers in the EV space will provide valuable insights into future wheel requirements.

lEmbrace Digitalization and Smart Manufacturing: The integration of Industry 4.0 technologies, such as AI and IoT, can help optimize the manufacturing process and improve quality control. By adopting digital twins and predictive analytic, manufacturers can enhance production efficiency and reduce waste, contributing to both cost savings and sustainability goals.

4. Case Study: A Successful Adaptation in the Wheel Market

A great example of adaptation in the car wheel market is the partnership between Schaeffler and Volkswagen Group. Schaeffler, a leading automotive supplier, developed an innovative hub bearing system for the Volkswagen ID.3 electric car. The bearing system was designed to handle the high torque demands of electric drive trains while also contributing to improved energy efficiency. This collaboration highlights how car wheel manufacturers can succeed by focusing on the unique needs of EVs and working closely with automakers to deliver advanced solutions.