5x114.3 Wheels: Global Buyer’s Guide to Fitment, Quality & Export Advantages

Why are 5x114.3 wheels getting all the attention?

Anchoring Value with Data: The "Golden Bolt Pattern" in the Global Market

In the automotive wheel hub industry, the 5x114.3 bolt pattern is hailed as the "King of Compatibility." According to the 2023 report by the International Automotive Parts Association (IAPA), approximately 35% of passenger vehicles worldwide are factory-equipped with this specification, covering over 200 mainstream models, ranging from economy sedans to high-performance sports cars. Its versatility is nearly unmatched.

Dominance of Compatible Models:

lJapanese Brands: Models like the Toyota Camry, Honda Accord, and Nissan Altima consistently rank among the top ten best-selling vehicles globally.

lAmerican Classics: Muscle cars like the Ford Mustang, Chevrolet Camaro, and Dodge Challenger, representing the muscle car culture.

lKorean Rise: Emerging market bestsellers such as the Hyundai Sonata and Kia K5.

lElectric Vehicle Segment: Electric models like the Tesla Model 3/Y and BYD Han EV also adopt this specification.

Behind this data is the long-standing trust that automakers have in the 5x114.3 design: The five-hole symmetric layout is more balanced in terms of mechanics, effectively dispersing centrifugal force during high-speed driving. It is also compatible with a wider range of wheel sizes (from 16 to 22 inches) and offset (ET) ranges, providing car owners with the freedom to modify their vehicles across multiple scenarios with a single specification.

The Invisible Driver Behind Industry Trends

With the global upgrade in automotive consumption, the wheel customization market has seen an annual growth rate exceeding 8% (according to Grand View Research). The 5x114.3 wheel, with its triple attributes of "high compatibility, high aesthetics, and high performance," has become the preferred specification for customization enthusiasts and wholesale buyers. Whether it's bulk purchasing by ride-hailing fleets in Southeast Asia or personalized orders from modification enthusiasts in Europe and North America, this bolt pattern remains the central point of convergence for both supply and demand.

Technical Analysis: What is a 5x114.3 Wheel?

Definition Explanation: Understanding Wheel Gene from the Numbers

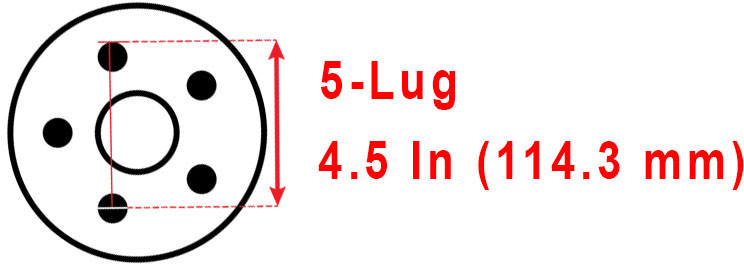

5x114.3 is a standardized expression for the bolt pattern of a wheel, composed of two key parameters:

"5": Represents the number of bolt holes on the wheel, which is 5.

"114.3": Refers to the diameter of the circle formed by the centers of the 5 bolt holes, which is 114.3 millimeters (equivalent to 5x4.5 inches in imperial units).

This specification is widely adopted by major automotive manufacturers globally. Its design strikes a balance between rigidity, lightweight construction, and production costs, making it the "golden standard" in the passenger car sector.

The 5x114.3 wheel's compatibility spans almost all car categories.

Cross-Model Coverage: From sedans, SUVs, pickups, sports cars, to electric vehicles, it covers all types.

Cross-Regional Penetration: From North America's muscle car culture to Asia's domestic market, and Europe’s performance tuning scene, it adapts without borders.

Cross-Scenario Application: Whether for daily commuting, off-road adventures, or track racing, it is compatible with corresponding wheel parameters for all scenarios.

Technical Advantages: Why is 5x114.3 the Common Choice for Tuning and Wholesale?

1. Stability: The Engineering Wisdom of the 5-Lug Design

Mechanical Advantage: Compared to 4-lug wheels, the 5-lug symmetrical layout disperses the contact stress between the wheel and the hub to more points, reducing the risk of fatigue fractures at a single point. In comparison to 6-lug wheels, it reduces weight and complexity, making it more suitable for lightweight passenger cars.

Test Data: In the ISO 14583 dynamic load test, the 5x114.3 wheel's resistance to deformation is 22% higher than that of the 4-lug design, with a lower probability of wheel distortion under extreme road conditions.

2. Compatibility: The "Universal Interface" of the Tuning Market

High ET (Offset) Flexibility: Supports wheel installation in the range of ET+35 to ET-15 (with adjustments based on wheel width), allowing for both a "flush" visual effect and avoiding brake caliper clearance issues.

Flexible J (Wheel Width) Matching: Customizable from 7J (suitable for 215mm tires) to 10J (suitable for 295mm wide tires), meeting the full range of needs from fuel-efficient narrow tires to track-ready wide tires.

Tuning Example: Taking the Honda Civic Type R as an example, the factory 5x114.3 wheel is 8.5J ET60, but during tuning, it can be upgraded to a 9.5J ET35 wheel with 265mm semi-slick tires, significantly improving grip without requiring any modifications to the fenders.

3. Supply Chain Efficiency: The Business Value of Global Standards

Stocking Cost Optimization: Wholesalers can centralize the purchase of 5x114.3 wheels, with a single SKU covering multiple vehicle models, reducing inventory pressure.

Simplified Modification Services: Repair shops do not need to frequently change adaptation tools, improving service efficiency.

Three Key Factors in Choosing 5x114.3 Wheels

For vehicle users who require 5x114.3 (PCD) wheels, the material, size compatibility, and compliance directly affect vehicle performance, safety, and longevity. Below are key points to consider from these three core aspects, with guidance based on industry standards and manufacturing processes to provide professional advice to consumers.

1. Materials and Craftsmanship: Balancing Performance and Cost

The material and manufacturing process of a wheel determine its strength, weight, and durability. Common manufacturing processes for 5x114.3 wheels include low-pressure casting, rotary casting, and forging, each with its own characteristics. Low-pressure cast wheels offer moderate strength, are heavier, and are cost-effective, making them suitable for daily commuting and economy vehicles. Rotary cast wheels provide higher strength and lighter weight at a moderate price, ideal for performance and modified cars. Forged wheels offer the highest strength and lightest weight, but at a higher price, making them commonly used in racing and high-end modified cars.

Company's Manufacturing Process Advantages:

X-ray Inspection: Detects internal pores or cracks to ensure the structural integrity of the wheel hub.

Salt Spray Testing: Simulates extreme corrosive environments to verify the durability of surface coatings, extending service life.

Dynamic Balancing Test: Reduces vibrations at high speeds, enhancing driving stability.

2. Size and Parameter Matching: Precisely adapted to vehicle performance

The 5x114.3 Wheel Hub Must Strictly Match the Following Parameters to Avoid Installation Failure or Performance Decline:

Wheel Diameter (16"-22")

Small Size (16"-18"): Thicker tire sidewalls provide better cushioning, suitable for family cars focused on comfort or complex road conditions.

Large Size (20"-22"): Lower aspect ratio enhances handling stability, but sacrifices some shock absorption. It is recommended to pair with a high-performance suspension system.

Wheel Width (J Value)

The J value determines the tire width matching range. For example, a 7.5J wheel matches 225-245mm wide tires. Too narrow or too wide may cause tire sidewall deformation or uneven wear.

Offset (ET Value)

The ET value affects the wheel's distance from the vehicle body. A small ET value may cause the wheel to protrude outward, potentially scraping the fender; while a large ET value may interfere with the brake system.

Adaptation Tools Support:

We provide a "Vehicle Model-Wheel Parameter Comparison Table." Users can contact customer service for a customized solution.

3. Certification and Compliance: Ensuring Global Market Access

International certification is the core guarantee for wheel safety and export compliance. Our products are certified in multiple countries and meet the regulatory requirements of target markets (DOT, TUV, JWL, ISO, etc.). We can provide complete certification documents to assist customers with customs clearance and market access.

Why Choose Us?

One-Stop Solution

We provide a comprehensive, one-stop solution for all your wheel needs. Whether you're looking for standard products or unique, customized solutions, we have the capability to support every step of the process—from design to delivery.

OEM/ODM Services

Our OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services cater to a wide range of requirements. We support customized designs, logo printing, and tailored packaging to match your specific brand and market needs. Our flexibility ensures that your product stands out while maintaining the highest standards of quality.

Wide Range of Sizes

We offer a full series of wheels, covering everything from economical options to high-end custom wheels. Whether you're looking for mass-production models or niche, performance-oriented designs, we provide wheels in a variety of sizes and specifications to suit all types of vehicles. Our broad selection ensures that you can meet both mainstream and specialized market demands effectively.

By choosing us, you gain access to industry-leading expertise and an extensive range of high-quality, customizable products that cater to diverse automotive needs.

Trade Support

Flexible Minimum Order Quantity (MOQ)

We offer flexible MOQ (Minimum Order Quantity) to tailor services based on different order volumes. Whether you require large-scale wholesale or small-batch custom orders, we provide suitable solutions to ensure a smooth procurement process. This flexibility is especially beneficial for startups, small businesses, or customers needing market-specific customizations, allowing you to test the market or expand with lower costs.

Export Services (Customs, Sea Freight, and Full-Service Logistics)

In addition to providing high-quality products, we offer comprehensive export services. Our export process covers the entire journey from product departure to final delivery, ensuring you don’t have to worry about complex customs procedures or international shipping. We assist with customs clearance based on the import regulations of different countries and regions, ensuring compliance and fast clearance. Furthermore, we collaborate with reliable international logistics companies to provide efficient and cost-effective sea freight solutions, ensuring your goods arrive safely and on time.

With our trade support, you can focus more on market expansion and brand development, while we handle the logistics and complex import/export procedures. We offer a one-stop service that helps reduce trade risks and enhance your competitiveness in the international market.

FAQ

Q1: How can I confirm if my vehicle is compatible with 5x114.3 wheels?

You can Google your vehicle’s make, model, and year to confirm the correct specifications. Alternatively, feel free to contact us and share your requirements, and we will help you determine the compatibility.

Visit website https://www.wheel-size.com/ or https://sizemywheels.com/ Come and inquire

Q2: Is it necessary to adjust the suspension or brake system after installation?

This depends on the specific scenario:

Upgrading from factory size (e.g., 18" → 19"): Typically, no adjustments are needed, but it's important to ensure the tire's overall diameter change is ≤3%.

Aggressive modification plans (e.g., significantly reducing ET or increasing J by more than 2 inches):

You may need to install wheel spacers to avoid rubbing against the brake calipers.

In extreme cases: You may need to upgrade the shock absorbers or adjust the suspension camber.

Q3: How is the wheel quality guaranteed?

We offer a 1-year warranty on the coating. If you encounter any quality issues after receiving the product, please feel free to contact us at any time.

Q4: What is the minimum order quantity and delivery lead time?

If the product is in stock, there is no MOQ restriction. For production orders, the MOQ depends on the product model and may be 40/60/80 pces.

It will generally take 30 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. For stock order, it will take 7 working days after receiving your advance payment.