Wheel Material Revealed: Cast Wheels vs Forged Wheels

Choosing the right passenger car aluminum alloy wheels is more than just about looks — it’s about performance, durability, and safety. Among the most common options available are cast wheels and forged wheels. Understanding the key differences between these two manufacturing methods will help you select the perfect alloy wheel Hub for your driving style and needs.

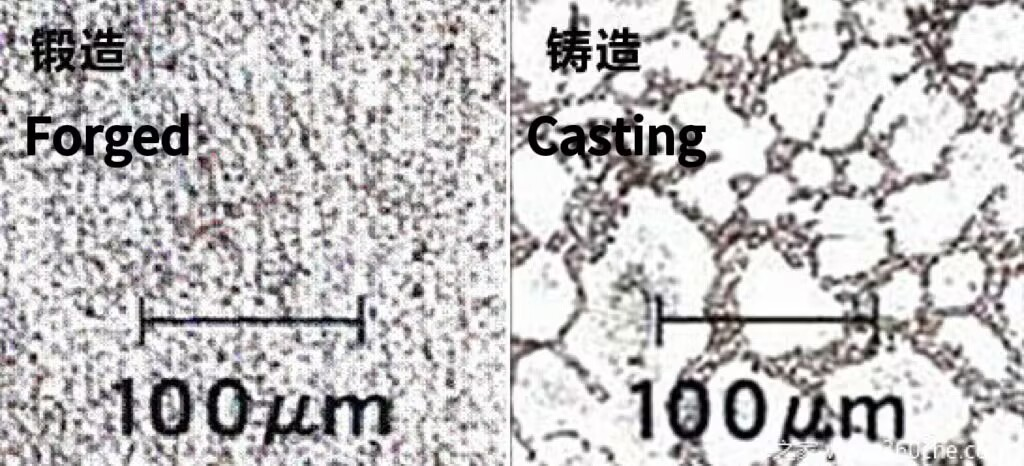

Cast wheels are made by pouring molten aluminum into a mold where it cools and hardens into shape. This process, known as casting, allows for more complex designs and is generally more cost-effective, making cast wheels a popular choice for many drivers. For example, many factory-stock sports cars come equipped with stylish cast aluminum rims because they strike a good balance between appearance and affordability. Cast wheels are lighter than steel wheels and offer improved handling and better fuel efficiency compared to heavier alternatives. However, because of the casting process, the material’s grain structure is less dense, making cast wheels more prone to cracking or bending under extreme stress or impact.

Forged wheels, in contrast, are produced by taking a solid piece of aluminum and applying extreme pressure and heat to shape it. This forging process compresses the material’s grain structure, resulting in a wheel that is significantly stronger and lighter than a cast wheel. This forging process eliminates internal voids and aligns the grain structure, resulting in a wheel that is stronger, lighter, and more impact-resistant. Forged wheels can withstand greater loads and impacts, making them ideal for high-performance vehicles, racing applications, and drivers who demand the highest standards of safety and performance. A good case in point is professional motor sport: nearly every Formula 1 and endurance racing team uses forged wheels for their cars, where even minor failures are unacceptable. The improved strength-to-weight ratio of forged wheels enhances handling, acceleration, and braking — advantages that performance enthusiasts deeply appreciate.

However, forged wheels come at a premium price. Their manufacturing process is more complex and time-consuming, which translates to higher costs. That said, for those who prioritize strength, weight reduction, and long-term durability, forged wheels are a worthwhile investment.

Consider a real-world example: A driver who occasionally takes their car to track days might find that cast wheels, while sufficient for daily driving, show signs of stress after a few sessions of aggressive driving. In contrast, forged wheels would easily handle the repeated strain without deformation, offering greater longevity and safety.

Of course, cost remains a crucial factor. Forged wheels can be two to three times more expensive than their cast counterparts. For everyday drivers focused on aesthetics and moderate performance, cast wheels present an excellent value. But for those seeking peak performance, reduced unsprung weight, and maximum reliability, forged wheels justify their higher price tag.

In conclusion, the choice between cast and forged wheels depends largely on your driving style, performance expectations, and budget. Whether you value affordability and design versatility or demand top-tier strength and weight savings, understanding the fundamental differences between cast and forged wheels ensures you make the best decision for your needs.